Our Services

We offer an extensive range of manufacturing services. This enables us to act as a true single-source supplier for all of your precision engineering needs.

Here at ADP Precision Engineering, our highly skilled team can produce high-quality components using our world-class modern engineering equipment.

Combine this with our unmatched capacity, flexibility, turn around times & on time delivery and of course quality performance and you can begin to see why our reputation is second to none!

Our Services

ADP are the ideal partner to help reduce costs and simplify supply streams and allow you to focus on your core activities and strengths.

Listed below are just some of the services that we can offer here at ADP Precision Engineering:

Precision Engineering - Milling / Turning

With over 2 Decades of experience in precision machining, ADP offer a wealth of knowledge and expertise to any project from concept to volume production. ADP produce class leading components in a wide range of materials thanks to our continued investment in market leading technology.

Outside Processing

Working closely with our partners ADP can offer a range of additional services making us an ideal supplier of turnkey solutions. We work closely with class-leading; welding & fabrication companies with a wide range of certifications. We can also offer laser profiling, water jet cutting & wire erosion.

Surface Treatment

We have a wealth of experience in coatings through working with some of the best coating companies in the UK. We are able to offer a wide range of finishes to suit your components. We can offer painting, anodising, or other specialist coatings/conversions to meet your requirements.

Material Testing

Here at ADP, we can offer a range of NDT material testing as well as manage the testing process through an approved metallurgy & metrology laboratory depending on your specific requirements and specifications.

Heat Treatment

Some of our components are required to work under severe stresses and in order for them to perform at optimal levels we often require a heat treatment to strengthen and harden certain materials. Along with our partners we are able to ensure that the exact heat treatment process is applied to meet your specifications.

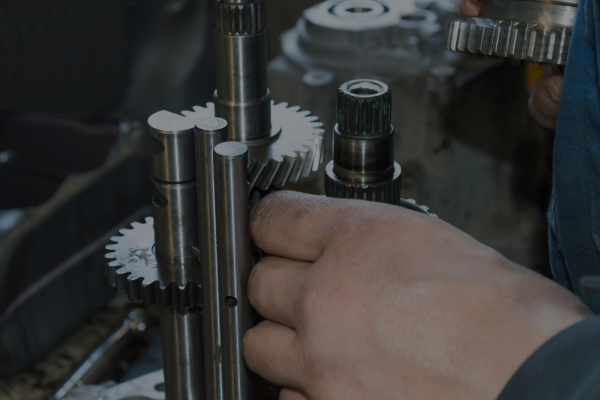

Assembly

As part of our processes, ADP can offer a full or sub-assembly process. Working with you ADP can tailor any project to suit your requirements. Helping to reduce BOM’s, improve quality and reduce lead times. Leaving you to focus on your core activities.

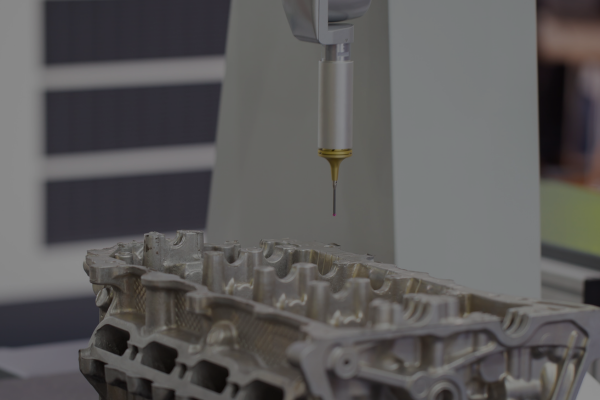

Inspection

All of ADP’s high-precision components go through our strict quality process, in our temperature-controlled inspection area using our Mitutoyo CMM meaning all our components meet your requirement and specification. We also have a Faro Arm, Mitutoyo Hardness Tester, Mitutoyo Surftest. Mitutoyo Linear Height gauge as well as standard inspection equipment.

CNC Turning and Milling

CNC Turning and Milling are key product services from ADP Precision Engineering. Whether your design requirement is simple of complex, large or small, our skilled machinists are able to produce the same consistency, quality and accuracy again and again. Everything that you would expect from the latest CNC Turning and multi axis CNC Milling machines operated and managed by one of the North East of England’s top precision engineering firms.

Our Plant list is extensive, ensuring that we have complete control and capability throughout the production lifecycle. At ADP Precision Engineering, our continual investment in machinery means you will find up to date and economical facilities from CAD technology to modern, efficient CNC lathes, CNC mills and the latest state of the art inspection equipment (including a new Faro Arm).

Operating 14 CNC machines from our 500 square metre facility, you can be assured that we can handle your requirements, from small orders to production volumes, through an on-going programme of investment in CNC machinery, ADP Precision Engineering have become one of the leading precision companies in the North East of England.

Materials

We work with an extensive range of materials. We can advise you on the cost implementations when considering a variety of materials for a particular application. Thanks to our experience in a very broad spectrum of customer markets, we have developed the skills and techniques required to deal with just about every material used in modern manufacturing. In addition to all the common metals and plastics used in engineering, we also have experience in manufacturing and machining from the following: Mild Steel, Alloy Steel, Stainless Steel, Brass, Plastics, Copper, Armour Plating, Titanium, Duplex, Aerospace Grade Aluminiums, Nitronic Hastelloy.

As well as working with a wide variety of ferrous and non-ferrous materials we are also specialists in the precision engineering of plastics. Working with plastics requires the development and implementatino of new extraction facilities of waste material. Some plastic composites are harder than steel but not as easy to work with. We have delivered a number of projects that have used CNC Turning and Millingtechnology using plastics to a high level of precision and complexity.

At ADP Precision Engineering, we routinely supply material conformity and mill certificates to clients. We hold a database of all information from previous batch production, if the part was manufactured more than once, details are instantly available.

Client Testimonials

Don’t just take our word for it, see what our clients have to say!